Potential applications of waste lignin from the paper and pulp industry in Viet Nam

- Department of Chemical Engineering, School of Biotechnology, International University, Ho Chi Minh City, Vietnam

- Industrial Development Center of Southern Vietnam, Ministry of Industry and Trade, 12 Nguyen Thi Minh Khai street, District 1, Ho Chi Minh City, Vietnam

- Department of Environmental Engineering, International University, Ho Chi Minh City, Vietnam

Correspondence to:

Thanh Khoa Phung,

Department of Chemical Engineering, School of Biotechnology, International University, Ho Chi Minh City, Vietnam.

Email:

ptkhoa@hcmiu.edu.vn.

Published:

2020-10-09

Abstract

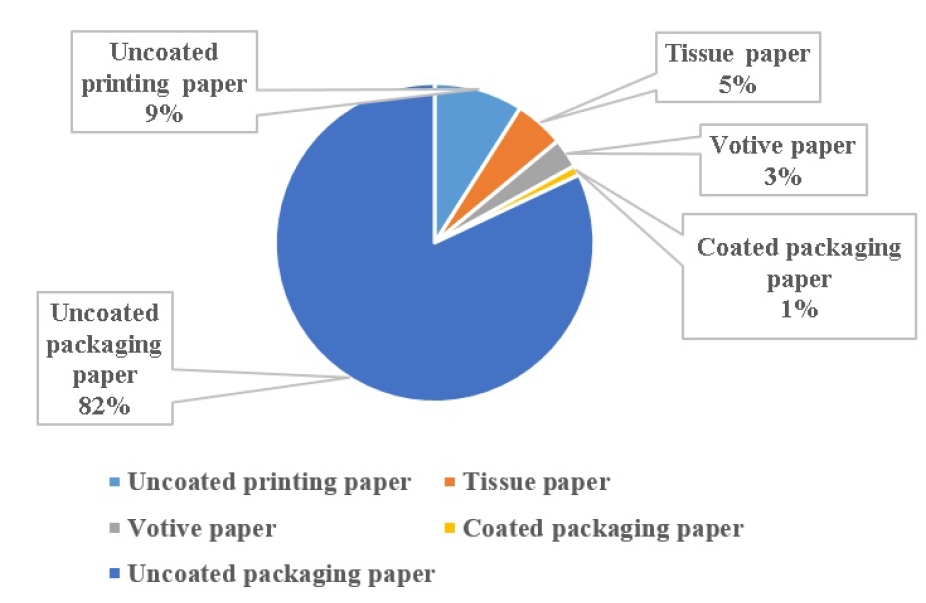

The conversion of waste lignin from the paper and pulp industry is a potential process to produce chemicals and materials in the industry. With the development and the demand for the pulp and paper industry, the amount of waste lignin will increase remarkably. In Vietnam, the forest tree for the pulp industry is abundant, and the pulp industry has increased in recent years. In parallel, the government planned to develop the material resource and high-tech factories for this industry. In this work, we summarized the pulp and paper industry in Vietnam, then suggest the potential applications of waste lignin in several valuable products.