Fabrication of astaxanthin emulsion and effect of cellulose derivatives

- Faculty of Chemical Engineering, Ho Chi Minh City University of Food Industry

- Faculty of Chemical and Food Technology, Ho Chi Minh City University of Technology and Education

Abstract

Introduction: Astaxanthin, a highly active oxidant, possesses a potential effect on human health. However, with the oily characteristic, the ability to disperse in an aqueous environment has limited its application. Therefore, the aim of this study is the fabrication of a stable astaxanthin emulsion in water.

Methods: In this study, an emulsion of astaxanthin was fabricated using polysorbate (tween 60/80) or lecithin. The dispersing methods of the magnetic stirrer and stator-rotor homogenizer were applied and compared. The effect of cellulose derivatives (sodium carboxymethyl cellulose (CMC), hydroxypropyl cellulose (HPC), hydroxyethyl cellulose (HEC), and hydroxypropyl methylcellulose (HPMC)) on the astaxanthin emulsion system was investigated. The samples were characterized using dynamic light scattering (DLS), a Brookfield viscometer and Fourier transform infrared (FTIR) spectroscopy.

Results: The homogenization could provide the system with a small Z-average value (~ 500 nm). The emulsion fabricated with lecithin maintained the red color of astaxanthin and homogeneity even after 5 months. Tween 80 had the worst effect on astaxanthin degradation because of the presence of double bonds in the surfactant’s molecular structure. The addition of soluble cellulose could significantly reduce the particle size and polydispersity even by using a magnetic stirrer. However, it could not ensure the protection of astaxanthin when phase separation was detected in many samples with polymers. The FTIR spectra and viscosity results revealed the strong interaction of lecithin with CMC, HEC, and HPC, which might be the reason for the low stability of the system. HPMC exhibited the best capability to stabilize and preserve the astaxanthin emulsion. Without using the high-energy dispersing method, a particle size of 482 nm (polydispersity index: 0.51) could be obtained with the HPMC-lecithin astaxanthin emulsion.

Conclusions: A stable astaxanthin emulsion (up to 5 months) could be fabricated successfully. The conventional homogenizer could form a better emulsion with a single surfactant. However, cellulose derivatives could assist the emulsion to have better DLS results even with the magnetic stirring method. Lecithin showed better performance in astaxanthin preservation than polysorbate surfactant. Strong interactions of lecithin with CMC, HEC, and HPC were detected. However, the addition of HPMC could provide a system with a lower particle size and high astaxanthin stability. The study could open a new approach for fabricating a stable astaxanthin emulsion using the low shear mixing method.

INTRODUCTION

Natural antioxidant compounds have been actively studied because of their potential applications and effect on human health1, 2. Astaxanthin (3,3’-dihydroxy-β, β’-carotene-4, 4’-dione), a naturally occurring xanthophyll carotenoid, was proven to be a powerful antioxidant3. It is a red pigment and can be found in various marine animals (salmon, trout) and organisms such as microalgae, yeast, and krill4. The astaxanthin structure consists of a conjugated polyene chain ending with two terminal rings. Its unique molecular structure could be used to explain its high antioxidant properties5, 6.

Because of its chemical structure, astaxanthin can only be dissolved in organic solvents and oily substances. Therefore, vegetable oil (olive, sunflower), ethanol, or acetone were applied to extract astaxanthin from microorganism sources7, 8, 9, 10, 11. The oleophilic properties might limit the application of astaxanthin in biorelated media. The polyene and terminal groups provide β-carotene with potential health effects. However, the structures could undergo multiple chemical reactions, which could lead to fast degradation, especially in the presence of free radicals and various oxidation reagents 12, 13. Carotenoids are highly sensitive to light exposure because the molecules might be excited to form free radicals 13, 14. Thermal degradation was also commonly observed in astaxanthin. The degradation of 69% of astaxanthin was detected after 120 h of storage at 4 °C, which is a popular temperature in household refrigerators15. Therefore, recent studies have focused on improving astaxanthin dispersion in water-based environments and enhancing the substance’s stability.

The encapsulation of astaxanthin could significantly improve both stability and bioavailability16. The oil-in-water (O/W) emulsion could be developed as an encapsulating technique for cosmeceutical17, 18 or medical applications 19. To form nano- or microemulsions, surface active reagents are usually added into the system. The emulsifier plays a very important role in minimizing the interfacial tension, which helps to disperse the oily liquid into the water phase 20. In addition, it also provided a protective effect to limit coalescence, which stabilized the system21, 22. Polysorbates (Tween 60 or 80), commercially available nonionic surfactants, are commonly applied to form nanoemulsions23, 24. For food applications, green and safe approaches are preferred25. Phospholipids (lecithin), surface active reagents from natural sources, have been widely used as emulsifiers26. However, the use of a single emulsifier might not have a sufficient effect. The combination of lecithin and Tween 80 has been investigated, and the structure of micelles formed depending on the ratio of lecithin/Tween 80 has been proposed27. In another approach, the emulsifier with the presence of various high-molecular-weight molecules might provide enhancement in the stability of the emulsion system. Chitosan in combination with a polysorbate emulsifier has been proposed to encapsulate citrus essential oil28. In another study, lysolecithin combined with sucrose monopalmitate was applied to stabilize the orange oil emulsion29.

Recently, cellulose derivatives have attracted attention for emulsion and encapsulation techniques owing to their biocompatibility and biodegradability 30. In addition, stable emulsions are usually formed with high-energy methods. The economical approach of applying the low-shear mixing method is still developing. However, to the best of our knowledge, no study has used cellulose derivatives to stabilize astaxanthin emulsions. With the aim of fabricating a stable astaxanthin emulsion, Tween 80/60 or lecithin was used as the main emulsifier to disperse astaxanthin in water. The effect of water-soluble cellulose derivatives on the stability of the emulsion system shall be investigated and discussed. The comparison of homogenizer and magnetic stirrer methods shall be performed in the presence of cellulose derivatives as a stabilizer.

EXPERIMENTAL SECTION

Materials

The chemical structures and abbreviations for the polymers used in this study are shown in Figure 1. Sodium carboxymethyl cellulose (CMC) and hydroxypropyl cellulose (HPC) (viscosity 2%, 20 °C: 1000-5000 mPa.s) were purchased from Nippon Paper Industries and Wako Pure Chemical Industries (Japan), respectively. Hydroxyethyl cellulose (HEC) (viscosity: 1500-2500 mPa.s) was the product of Aladdin Industrial Corporation (Shanghai, China). The hydroxypropyl methylcellulose (HPMC) used in the research is an E6 type of Shandong Head (Shandong, China). Polysorbates of Tween 60 and 80 were obtained from Guangdong Guanghua Sci-Tech Cop. (China). Lecithin is the product of Chengdu Bright (China). The oleoresin form of astaxanthin 10 wt% (Astalif 10) was obtained from Algalif (Iceland).

Chemical structures of cellulose derivatives (CMC, HEC, HPC, and HPMC).

Sample preparation

Polysorbate (500 μL, Tween 60 or 80) or lecithin (0.5 g) was dispersed in 100 mL double distilled water using a magnetic stirrer (IKA, C-Mag HS 7) for 60 min. Then, astaxanthin (0.05 g) was added, and the mixture was emulsified using a stator-rotor homogenizer (5000 rpm) (T 25 Ultra Turax Digital, IKA, Germany) (for DH samples) or a magnetic stirrer (speed: scale 3) (C-Mag HS 7, IKA, Germany) (for KT samples). The samples marked as 60, 80 and Lec represented the fabrication methods using Tween 60, 80, and lecithin, respectively. In the case of the samples using cellulose derivatives as a cosurfactant, the polymer (0.5 g) was first dissolved in 100 mL double distilled water before adding surfactant (Tween 60/80 or lecithin). The mixture of polymer and surfactant was stirred for 60 min before fabricating the astaxanthin emulsion using a similar technique.

Characterization

Dynamic light scattering (DLS)

The particle size of the emulsion could be analyzed using the dynamic light scattering (DLS) technique31 (Zetasizer Pro, Malvern, UK). The forward scattering mode and the detector placed at an angle of 17° were applied. The sample was equilibrated for 60 s at the measuring temperature (25 °C) before carrying out the measurement. The DLS results included both values of Z-average (along with the polydispersity index) based on cumulant analysis, and the intensity distribution peak size was reported. The measurement was repeated three times. The average values and standard deviation were reported.

Viscosity32

The viscosity of the solution was obtained by using a rotational viscometer (Brookfield, model: DV2T, USA). The instrument was connected to the spindle of RV-03 (Brookfield). The rotational speed of the spindle varied from 1 to 100 rpm.

Fourier transform infrared spectroscopy (FTIR)

The polymer and the mixture with the used surfactants were fabricated in an aqueous form without the presence of astaxanthin. The solution was cast on a petri dish. The solvent was evaporated gradually under ambient conditions to form the film samples. FTIR spectra were obtained in the 4000 - 400 cm region using the attenuated total reflection (ATR) technique and MIR/NIR Frontier Perkin Elmer equipment.

Turbidity

Turbidity is also another important factor to evaluate the emulsion system33. Therefore, the emulsion solution was also evaluated with the turbidity parameter. The values in formazin nephelometric units (FNU) were obtained using a turbidity meter (Mi415, Milwaukee Instrument, USA).

RESULTS

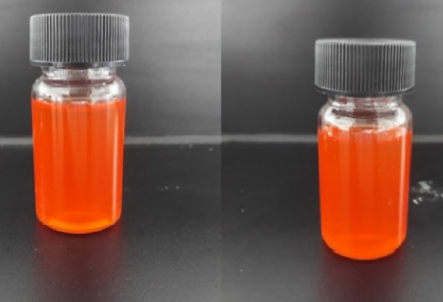

An emulsion system of astaxanthin with various surfactants (Tween 60, 80, and lecithin) was fabricated. The images of the samples after preparation using a homogenizer are shown in Figure 2. The samples were in the homogenous red state, indicating that astaxanthin could be well dispersed in the aqueous solution.

Astaxanthin emulsion samples were prepared by homogenization with different surfactants.

DLS and turbidity results of astaxanthin emulsion prepared using polysorbate

|

Sample |

Peak Mean by Intensity (nm) |

Z-Average (nm) |

PDI |

Turbidity (FNU) |

|

DH.60 |

492 ± 66 |

509 ± 82 |

0.43 ± 0.20 |

249 |

|

KT.60 |

641 ± 36 |

880 ± 41 |

4.29 ± 1.85 |

706 |

|

DH.80 |

571 ± 68 |

959 ± 113 |

11.22 ± 7.64 |

245 |

|

KT.80 |

539 ± 88 |

716 ± 120 |

3.50 ± 0.67 |

397 |

DLS and turbidity results of astaxanthin emulsions prepared using lecithin

|

Sample |

Peak Mean by Intensity (nm) |

Z-Average (nm) |

PDI |

Turbidity (FNU) |

|

DH.Lec |

487 ± 66 |

489 ± 45 |

0.62 ± 0.42 |

> 1000 |

|

KT.Lec |

420 ± 27 |

542 ± 80 |

3.23 ± 2.16 |

> 1000 |

Astaxanthin emulsion samples after 5 months were prepared by homogenizing (DH samples) with the surfactants of (a) Tween 60, (b) Tween 80, and (c) lecithin.

The next investigation includes the combination of surfactants and water-dissolvable polymers. The DLS results of the systems prepared with Tween 60 and cellulose derivatives are shown in

Astaxanthin emulsion after 5 months prepared with Tween 60 surfactant and various polymers.

DLS results of emulsion samples prepared with Tween 60 and cellulose derivatives

|

Sample |

Peak Mean by Intensity (nm) |

Z-Average (nm) |

PDI |

Turbidity (FNU) |

|

DH.60.CMC |

752 ± 109 |

910 ± 90 |

2.52 ± 0.39 |

186 |

|

KT.60.CMC |

740 ± 163 |

1341 ± 107 |

12.06 ± 6.05 |

401 |

|

DH.60.HEC |

591 ± 32 |

728 ± 26 |

2.27 ± 0.70 |

210 |

|

KT.60.HEC |

461 ± 9 |

447 ± 37 |

0.24 ± 0.14 |

163 |

|

DH.60.HPC |

650 ± 23 |

849 ± 136 |

3.39 ± 2.21 |

211 |

|

KT.60.HPC |

409 ± 43 |

404 ± 27 |

0.24 ± 0.21 |

172 |

|

DH.60.HPMC |

451 ± 65 |

455 ± 52 |

0.16 ± 0.06 |

235 |

|

KT.60.HPMC |

404 ± 9 |

395 ± 44 |

0.36 ± 0.43 |

276 |

In another investigation, water-soluble cellulose derivatives were added to an emulsion prepared with Tween 80, and the DLS results of the formed solutions are summarized in

DLS results of emulsions prepared with Tween 80 and cellulose derivatives

|

Sample |

Peak Mean by Intensity (nm) |

Z-Average (nm) |

PDI |

Turbidity (FNU) |

|

DH.80.CMC |

673 ± 20 |

708 ± 14 |

0.70 ± 0.13 |

148 |

|

KT.80.CMC |

611 ± 55 |

651 ± 128 |

0.84 ± 0.83 |

69 |

|

DH.80.HEC |

600 ± 93 |

776 ± 212 |

3.06 ± 2.27 |

254 |

|

KT.80.HEC |

424 ± 77 |

441 ± 102 |

0.35 ± 0.35 |

108 |

|

DH.80.HPC |

570 ± 49 |

582 ± 48 |

0.31 ± 0.10 |

391 |

|

KT.80.HPC |

467 ± 36 |

461 ± 60 |

0.43 ± 0.39 |

189 |

|

DH.80.HPMC |

527 ± 30 |

563 ± 27 |

0.61 ± 0.06 |

284 |

|

KT.80.HPMC |

423 ± 23 |

434 ± 38 |

0.44 ± 0.50 |

167 |

The stability of the formed emulsion was monitored, and the captured images after 5 months of storage are shown in Figure 5. Unfortunately, although the size distribution was significantly improved by adding a cellulose derivative, the astaxanthin preservation capability could not show good results. All emulsion samples based on Tween 80 were severely unstable even under cold storage conditions.

In the next experiment, the phospholipid surfactant was combined with the polymers to confirm the capability of further improvement. Similarly, the DLS technique was applied to determine the particle size of the formed emulsion, and the images of the samples were rechecked after storage for at least 5 months. As can be observed, compared to the samples with only lecithin, all samples that applied magnetic stirring showed significantly smaller particle sizes. However, the PDI values in the cases of the homogenizer were higher when the polymers were added. In the case of lecithin, the stability investigation showed a better result. Although phase separation might be observed in some samples, the red color of astaxanthin was maintained. The most homogeneous state was obtained with the assistance of HPMC.

Astaxanthin emulsion after 5 months prepared with Tween 80 surfactant and various polymers.

Astaxanthin emulsions after 5 months were prepared by homogenizing (DH) or magnetic stirring (KT) with lecithin surfactant and various polymers.

DLS results of emulsions prepared with lecithin and cellulose derivatives

|

Sample |

Peak Mean by Intensity (nm) |

Z-Average (nm) |

PDI |

|

DH.Lec.CMC |

623 ± 76 |

608 ± 165 |

0.55 ± 0.68 |

|

KT.Lec.CMC |

586 ± 49 |

492 ± 82 |

0.17 ± 0.13 |

|

DH.Lec.HEC |

492 ± 28 |

586 ± 36 |

1.75 ± 0.48 |

|

KT.Lec.HEC |

468 ± 21 |

454 ± 44 |

0.32 ± 0.46 |

|

DH.Lec.HPC |

514 ± 12 |

662 ± 51 |

3.07 ± 1.78 |

|

KT.Lec.HPC |

487 ± 24 |

476 ± 5 |

0.13 ± 0.10 |

|

DH.Lec.HPMC |

390 ± 38 |

475 ± 116 |

2.30 ± 2.60 |

|

KT.Lec.HPMC |

466 ± 32 |

482 ± 7 |

0.52 ± 0.51 |

The viscosity of the polymer solutions with lecithin.

In general, the astaxanthin protection capability with lecithin was better than that with polysorbate. However, the performance varied depending on the type of cellulose derivative used. For a deeper understanding, viscosity measurements were conducted to investigate the interaction between lecithin and the cellulose derivatives. The results are summarized in Figure 7. Among the polymers, the HPMC solution remained unchanged. The viscosity of the CMC solution was dramatically reduced when lecithin was added. In contrast, HEC and HPC solutions slightly increase the viscosity in the presence of lecithin.

FTIR spectra of cellulose derivatives and lecithin combinations.

DISCUSSION

When only surfactant was used, a small size and low dispersity emulsion system were only obtained by applying a homogenizer with Tween 60 and lecithin. In the single surfactant system, the degradation rate of astaxanthin also correlated well with the particle size analysis. The small size and low polydispersity emulsion maintained its strong red color and homogeneity after 5 months of investigation. The Tween 80 system with a large particle size and polydispersity could not yield a good storing effect of astaxanthin. However, superior results were only obtained with the high energy dispersing method of the conventional homogenizer. The high speed of the homogenizer provided a good capability to disperse the oily substances in water. In addition, it might also generate heat during mixing. Therefore, it might accompany the possibility of thermal degradation of the highly sensitive compounds even in the preparation step. It is worth noting that the technique in this study is the stator-rotor homogenizer. Therefore, the particle size was rather large because of the use of the conventional homogenizer. Although the nanosize could be obtained in other studies using polysorbate31, 34, the preparation steps required a high-pressure homogenizer. The samples subjected to only magnetic stirring could not form small and homogenous particles. Interestingly, many cases showed low PDI and small size by adding water-soluble cellulose derivatives. The astaxanthin oil was covered by the main surfactant and might be further stabilized with the presence of cellulose molecules. However, except for a few cases of DH.60. HPMC, DH.80. CMC, DH.80. HPMC, and DH.Lec. CMC, most of the homogenized samples using the polymeric stabilizer showed larger particle sizes, and the systems were highly unstable. It is possible that by applying a strong dispersive force, a smaller size of astaxanthin oil might be formed. As a result, the surface area was increased. Therefore, the amount of surfactant was not enough to cover all of the formed oily particles. The remaining uncovered portion of astaxanthin particles might interact with the hydrophobic main chain of the polymers. Then, the polymer chains could be linked inner or intermolecularly to form a larger cluster. On the other hand, with magnetic stirring, the surfactant amount was enough to cover the oily phase. Without the polymer, these systems with a single surfactant showed the ability to reaggregate. With the presence of cellulose derivatives in the solution, the micelles were stabilized and prevented the formation of larger particles.

However, when the polymers were added as cosurfactants, the correlation between particle size and astaxanthin preservation could not be determined. However, some samples with low dispersity and small particle size could still not show enhancement in astaxanthin stability. Although the polymers were added, the performance with Tween 60 was still better than that with Tween 80. The reason for this phenomenon might relate to the difference in the chemical structures. Compared to Tween 60, Tween 80 molecules contain double bonds. Every double bond includes a sigma bond and a pi bond that can easily react with electrophile reagents. Therefore, the stability of astaxanthin could not be ensured under the cover of high reactivity substances.

As can be observed in the results section, the performance of lecithin in restraining astaxanthin degradation was better than that of polysorbate. Although phase separation was still observed, many samples could preserve the strong red color of astaxanthin even after 5 months. The particle size obtained with lecithin in the current study could not be compared to the results reported in other studies35, 36. However, the stability of astaxanthin could still be maintained. The proposed preparation was less energy-consuming, while a high-pressure homogenizer 37 or ultrasonication35 had to be applied in other reports. However, the addition of polymer to the lecithin-based emulsion could not further reduce the particle size. However, many samples showed significant improvement in PDI values. Conversely, in the presence of polymer (except CMC), the polydispersity performed better by using magnetic stirring. The result might open an original approach to have a better size and dispersity with a low shear method. The sample with HPMC maintained the homogeneous state even after 5 months. The viscosity measurement also gave an inside of the interaction between lecithin and the cellulose derivatives. Among the polymers, CMC showed the strongest interaction, while lecithin could not show any observable effect on the viscosity of the HPMC solution. The lecithin molecules contained charges that might strongly combine with CMC molecules owing to the ionic interaction. Therefore, the large polymer molecules should be coiled or self-aggregated, and the viscosity of the solution could be dramatically decreased. The other cellulose derivatives (HEC, HPC, and HPMC) only slightly varied in alkyl groups. The HPMC molecule contains methyl and propyl hydroxyl side groups and might achieve a good balance between hydrophobic and hydrophilic properties. Compared to the original cellulose molecules, the FTIR spectrum of the polymer-lecithin mixture was dominated by new peaks due to the presence of phospholipids. Only the HPMC and lecithin spectra showed an equal combination of the two original components. In this case, the strong interaction between the cellulose molecules and the main surfactant might deteriorate the capability to emulsify astaxanthin. Therefore, HPMC showed the best performance in the stability of the emulsion state as well as the strong red color of astaxanthin.

CONCLUSIONS

The emulsion of astaxanthin in water was fabricated successfully, and the stability could be maintained for 5 months. Without the presence of cellulose derivatives, the homogenizer could form a better emulsion. The addition of CMC, HEC, HPC, and HPMC could significantly improve the particle size and PDI value by simply applying the low energy dispersion of the magnetic stirring method. Between the two types of polysorbate, Tween 80 provided the worse effect on astaxanthin. This might be related to the double bonds contained in Tween 80 molecules. The correlation between particle size and the ability to prolong the red color of astaxanthin could only be made without the presence of cellulose derivatives. With the addition of polymer as the stabilizer, although the emulsion size was smaller and the dispersity was better, it could not always ensure the protection of astaxanthin against deterioration. The capability to limit astaxanthin degradation was better with lecithin. The FTIR and viscosity measurements detected the strong interaction of lecithin with CMC, HEC, and HPC, which might be a reason for the weak stability of the emulsion. HPMC was proven to provide good results with lecithin when the red color of the astaxanthin emulsion remained after 5 months. Without using the high shear method of the homogenizer, the simple magnetic stirring of the astaxanthin emulsion could achieve a particle size of 482 nm and a PDI of 0.521 in the presence of HPMC.

Abbreviations

CMC: Sodium carboxymethyl cellulose

HPC: Hydroxypropyl cellulose

HEC: Hydroxyethyl cellulose

HPMC: Hydroxypropyl methylcellulose

DLS: Dynamic light scattering

PDI: polydispersity index

FTIR: Fourier transform infrared spectroscopy

Acknowledgments

Authors would like to thank Ms Le Thi Kim Anh adn Ms Truong Thi Phuong Dung for providing laboratory services.

Author’s contributions

Ha N. Giang developed ideas and wrote the manuscript. Ha N. Giang carried out DLS measurements. Loan T. Nguyen and Tuan N. A. Huynh prepared the samples and conducted the other experiments. Ha. N. Giang analyzed and provided discussion of the obtained results.

Funding

This work was funded by Ho Chi Minh City University of Food Industry (contract number 143 HĐ/DCT, date: Oct 1, 2022).

Competing interests

The authors declare that they have no competing interests.