The effect of temperature and reaction time on the physicochemical properties of oxidized bacterial cellulose membranes for hemostatic dressings

- Department of Tissue Engineering and Regenerative Medicine, School of Biomedical Engineering, International University, Ho Chi Minh City, Vietnam

- Vietnam National University in Ho Chi Minh City, Ho Chi Minh City, Vietnam

Abstract

The development of an oxidized bacterial cellulose membrane (OBC) for hemostasis application is essential for preventing death from excessive bleeding. In previous research, OBC membranes were fabricated by using many different oxidation systems, notably the HNO3/H3PO4-NaNO2 system. In this study, the effects of oxidation conditions, such as temperature and reaction time, on the structure and physicochemical properties of OBC for hemostasis dressings oxidized by a mixture of HNO3/H3PO4-NaNO2 were investigated. The morphology of the OBC membranes was observed using a scanning electron microscope. Chemical modification was confirmed using Fourier transform infrared spectroscopy and carboxyl content analysis. The mechanical properties of the OBC membranes before and after oxidation were also evaluated by tensile testing. The results revealed an increase in the carboxyl content and a decrease in the mechanical properties of the OBC membranes with increasing temperature and reaction time. The results indicate that under the temperature and time conditions of the survey, the OBC membrane oxidized at 40 °C for 6 hours had a relatively high carboxyl content of 16.18% (suitable for hemostasis dressing) while maintaining sufficient mechanical strength for wound dressing application.

Introduction

Hemorrhagic shock is one of the main causes of death worldwide. Approximately one-third of the approximately six million trauma-related deaths are attributable to hemorrhagic hemorrhage 1. Numerous of these are regarded as preventable fatalities. The risk of death can be considerably decreased if local bleeding can be controlled appropriately 2. It is therefore vitally important to develop biomaterials with hemostatic functions. Currently, research on topical hemostatic products is growing. These topical hemostatics are based on various polymers, such as chitosan, oxidized dextran 3, and oxidized cellulose (OC)4. Among the listed polymers, OC is the most popular and effective hemostatic agent.

OCs are a class of polymers derived from cellulose that are obtained through the oxidation of either synthetic or natural cellulose 5. It has been proven that OC is an ideal hemostatic material, making it a reliable, widely used, safe, and efficient hemostatic agent for surgical hemostasis based on carboxyl groups that are formed after oxidation. OC exhibits strong hemostasis and can be used to control bleeding when the carboxyl content is between approximately 16 and 24% 6. In recent research, OC was oxidized by several oxidizing systems: the HNO/HPO-NaNO system7, the NO–HNO system8, the KCl/HCl-NaIO system9, the TEMPO-mediated system 10, and others. Among them, the HNO/HPO-NaNO system is a popular system.

Among the cellulose types, bacterial cellulose (BC) has attracted great attention because of its many applications in biotechnology, pharmaceuticals, biobased packaging, and other scientific fields. The reason is based on the easy production of pure cellulose materials with good mechanical properties, high purity, bondability, and high humidity 11. The high water absorption and gas permeability of BC hydrogels enable the exchange of nutrients necessary for bacterial survival. The unique physicochemical properties of bacterial cellulose are comparable to those of plant cellulose. The functional groups on BC can be chemically modified to develop functionalized BC with a multitude of different applications12. Among BC materials, nata de coco (NC) is the most popular BC in Vietnam and is produced by the fermentation process using coconut oil. Due to their characteristic properties, such as biocompatibility, high purity, high humidity, and high physical properties, NC has been applied in various medical applications, such as in many desserts, papermaking, heavy metal-contaminated wastewater treatment, and biomedicine (drug delivery, wound healing, tissue restoration). Although NCs show promising properties that could be applied in the biomedical engineering field, they are not suitable for hemostasis applications. The hydroxyl functional groups of NCs do not contribute to the platelet activation process due to their neutral charge. Therefore, the chemical structure of NC should be modified to generate a carboxyl functional group by an oxidation process, which is beneficial for hemostasis. The hemostatic mechanism of oxidized bacterial cellulose (OBC) or oxidized NC is based on the negative charge provided by the carboxyl groups formed after oxidation. The blood coagulation process was started by changing the conformation of the coagulation factor FXII when it was adsorbed. The adsorption of the coagulation factor FXII can be more intense on negatively charged surfaces.

According to previous research, the physical and chemical properties of BC are strongly affected by oxidation. In recent research, the effects of HNO/HPO ratios and temperature on the properties of OBC with several resources, such as cotton linter sheets, bamboo pulp yarns, and nata de coco pieces, were surveyed. However, the effect of temperature and reaction time on the properties of the OBC membrane from the nata de coco sheet oxidized by using the HNO/HPO-NaNO system has not been examined. Furthermore, the mechanical properties of the BC membrane decreased as the number of carboxyl groups increased. Therefore, the oxidation parameters of NC should be evaluated to produce an oxidized NC membrane that is suitable for use as a hemostasis dressing.

In this study, the effect of reaction conditions, such as temperature and reaction time, on the properties of an OBC membrane fabricated by oxidizing a fixed-size nata de coco membrane using a mixture of HNO/HPO-NaNO was examined. The morphological, chemical, and mechanical properties of the OBC membranes were evaluated by numerous analytical methods to determine the effect of oxidation parameters. The chosen OBC membranes are those that are suitable for hemostasis dressing applications.

Materials and Methods

Materials

BC (Nata de Coco) sheets (Minh Tam Co., Ltd., Ben Tre Province, Vietnam) were used as a bacterial cellulose resource. Sodium nitrite, nitric acid, and phosphoric acid were purchased from Xilong Scientific Co., Ltd., China. These chemicals were used without any further modification.

Preparation of OBC membranes

The BC membranes were purified before oxidation. The BC membranes were boiled at 100 °C for one hour and then immersed in a 1 M NaOH solution for 24 hours. Afterward, the BC membranes were washed with deionized water to remove bacteria and impurities. Subsequently, the purified BC was completely soaked in a mixture of nitric acid and phosphoric acid (with a ratio of 1:3 v/v). Sodium nitrite (1.4% w/v) was added to the mixture. The reaction times were 6, 12, and 24 hours at 25, 40, 55, and 70 °C, respectively. Then, the OBC membrane was rinsed with deionized water several times until the acid in the membrane was completely removed. Finally, the OBC membrane was dried in a cold dryer and preserved under cool conditions. The sample names were determined according to the synthesis parameters. For example, the OBC sample obtained after 6 hours at 25 °C was named OBC-6 h-25.

Characterization

The BC and OBC samples were cut into 1 cm × 1 cm membranes. Before analysis, they were sputter-coated with gold to minimize the charging effect. Scanning electron microscopy (SEM) (JSM-IT100, JEOL, Japan) was used to observe the morphology of these membranes.

The functional groups of the OBC membranes were analyzed by FT-IR analysis (Bruker Vertex 70 FT-IR spectrometer, Germany) in the wavenumber range of 4000-400 cm.

The 0.5 g weight samples were cut into small particles and then treated with 25 ml of 0.01 M HCl for an hour to obtain the acidic form by replacing its cations with hydrogen ions. After that, they were washed with deionized water three times in 30 min. Then, 50 ml of a 2% (w/w) calcium acetate solution was added to the above mixture. After ultrasonic mixing for 30 min, the mixture was titrated with 0.1 M sodium hydroxide. The carboxyl content in the sample was evaluated by the following equation13:

Carboxyl content (%w/w) =

where is the volume (ml) of NaOH solution used for titrations, is the molecular weight of the carboxyl group (45 g/mol), is the weight of the OBC (mg), and is the humidity of the OBC (%).

The OBC membranes were cut into dog-bone-shaped specimens, and their thicknesses were recorded by an electronic caliper. Then, their tensile strengths were measured using a texture analyzer (TA. XTplus, Stable Micro Systems, USA) at room temperature and humidity (25 °C, 65% RH) to examine the effect of oxidation on their mechanical properties. At least five samples were tested for each condition group.

The use of human blood and the blood collection method for this research were approved by the Institutional Ethics Review Committee of Vietnam National University in Ho Chi Minh City (No. 07/QĐ-IRB-VN01.017). After being taken from donors, whole blood was put into anticoagulation tubes with 3.2% w/v sodium citrate. Before the BCI test, whole blood was supplemented with 0.1 M CaCl. The sample was prepared at a size of 1 cm x 1 cm, put into a 24-well plate, and incubated at 37 °C. Fifty microliters of recalcified whole blood was dropped onto the surface of each sample. The sample was then prewarmed at 37 °C for 5 minutes. The negative control sample was a blood sample with anticoagulant, no recalcification, and no contact with the sample. After the incubation period, 2 mL of distilled water was added to each well. The plate was incubated at 37 °C for 10 minutes. Then, 100 µL of solution from each well was transferred to a new well of the 96-well plate. A well containing only distilled water was used as a blank sample. The absorbance of the 96-well plates was measured at 540 nm using a microplate reader (Varioskan LUX series, Thermo Fisher, USA). The BCI was calculated by the following formula:

where is the average absorbance value of the survey sample and is the average absorbance value of the blank sample.

Statistical analysis

One-way analysis of variance (ANOVA) and p < 0.05 were used to determine significant differences in each of the samples.

Results

OBC membrane morphologies

Figure 1 shows the changes in the morphology of the bacterial cellulose membranes after oxidation. As is evident from the photographs, 4 samples still retain their membrane shapes after oxidation, such as OBC-6 h-25 (Figure 1a), OBC-6 h-40 (Figure 1b), OBC-12 h-25 (Figure 1e), and OBC-24 h-25 (Figure 1i). However, the structures of other membranes were damaged, and these membranes were broken and lost some parts during oxidation.

OBC samples after oxidizing with different reaction times and temperatures: (a) 6 hours – 25 °C, (b) 6 hours – 40 °C, (c) 6 hours – 55 °C, (d) 6 hours – 70 °C, (e) 12 hours – 25 °C, (f) 12 hours – 40 °C, (g) 12 hours – 55 °C, (h) 12 hours – 70 °C, (i) 24 hours – 25 °C, (j) 24 hours – 40 °C, (k) 24 hours – 55 °C, (a) 24 hours – 70 °C.

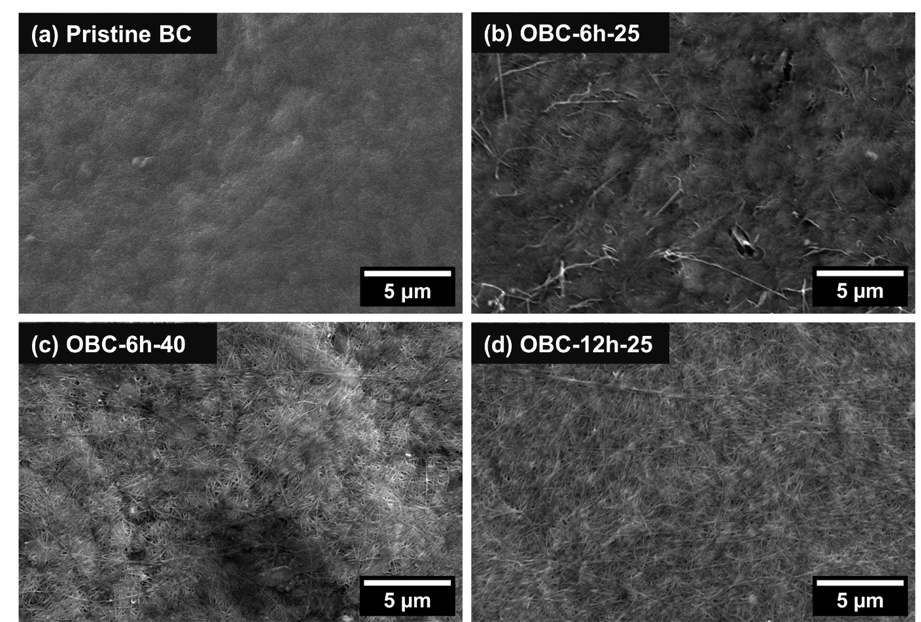

SEM images of (a) BC, (b) OBC-6 h-25, (c) OBC-6 h-40, (d) OBC-12 h-25, and (e) OBC-24 h-25 samples.

(a) FT-IR spectra and (b) carboxyl content of BC, OBC-6 h-25, OBC-6 h-40, OBC-12 h-25, and OBC-24 h-25 samples.

(a) stress‒strain curves, (b) strength–elongation at maximum stress, and (c) Young’s modulus – toughness of BC, OBC-6 h-25, OBC-6 h-40, OBC-12 h-25, and OBC-24 h-25 membranes, and (d) BCI of OBC-6 h-40 sample.

The oxidation reaction of BC by using the HNO3/H3PO4-NaNO2 system.

SEM images of the pristine BC and OBC membranes with different oxidation parameters are presented in Figure 2. As seen from the SEM images, both the BC (Figure 2a) and OBC (Figure 2b – Figure 2e) membranes appeared to have smooth surfaces and closely linked, stacked microfibers that were randomly intertwined to form a dense cellulose matrix system. However, after the oxidation process, the surfaces of the OBC membranes were rough, with the appearance of broken fibers.

Physicochemical properties and hemostasis performance of the OBC membranes

The FT-IR spectra in Figure 3a show the changes in the functional groups of the BC membrane after oxidation. These spectra were normalized by a peak at 1055 cm-1 corresponding to the C-O-C vibration of the sugar ring of BC 14. As shown in Figure 3a, the OBC membranes still retained the characteristic peaks of BC, such as those at 898 cm, 1055 cm, 1200–1500 cm, 1640 cm, 2898 cm, and 3000–4000 cm. The peaks between 3000 and 4000 cm were associated with the O–H stretching vibration of cellulose, while the peak at 2898 cm corresponded to the C–H stretching vibration15. The peaks at 1640 cm and 1055 cm indicated the bending vibrations of the adsorbed water molecules and the C–O–C pyranose ring stretching vibration, respectively16. The absorption peak at 898 cm was related to the cellulosic b-glycosidic linkages in bacterial cellulose16. In addition, in the FT-IR spectra of the OBC membranes, a new absorption peak was observed at approximately 1727 cm which was related to the stretching vibration of the -C=O bonds of carboxyl groups in the OBC membranes 17. The appearance of the new peak confirmed that the BC was successfully oxidized.

The effect of temperature and reaction time on the chemical structure of OBC is indicated by the amount of carboxyl groups (Figure 3b) formed in the BC membranes after oxidation. Overall, the carboxyl content of the OBC samples corresponds to the increase in temperature and oxidation time. There was considerable growth in the carboxyl content from 1.17% (OBC-6 h-25) to 16.18% (OBC-6 h-40) when the temperature increased from 25 °C to 40 °C. The percentage of carboxyl groups increased from 1.17 to 23.63% when the reaction time increased from 6 h (OBC-6 h-25) to 24 h (OBC-24 h-25).

Figure 4a, b, and c compare the mechanical properties of BC and OBC oxidized with different parameters. The pristine BC sample shows the highest mechanical strength of 6.10 MPa and elongation at a maximum stress of 59.2%. After the oxidizing process, the strength of OBC decreased, while the elongation of OBC at the maximum stress increased. OBC-6 h-25 exhibited reduced mechanical properties, with a strength, Young’s modulus, and toughness of approximately 4.82 MPa, 1.54 MPa, and 2.07 MJ/m, respectively. Further oxidation decreased the strength, Young’s modulus, and toughness of OBC-24 h-25 to 1.33 MPa, 0.60 MPa, and 0.55 MJ/m, respectively. Regarding the reaction temperature, the OBC membrane treated at 40 °C exhibited lower mechanical strength than that treated at 25 °C. In particular, the strength, Young’s modulus, and toughness of OBC-6 h-40 were 2.25 MPa, 0.55 MPa, and 0.94 MJ/m, respectively.

The results in Figure 4d show the BCI of the OBC and BC samples. The OBC sample has a significantly lower BCI value than the negative control sample, indicating that the OBC sample supports blood clotting and thrombosis. This value of the OBC sample is also significantly lower than that of the BC sample.

Discussion

This study focused on fabricating an OBC membrane prepared from BC membranes oxidized at several temperatures (25, 40, 55, and 70 °C) and different reaction times (6, 12, and 24 h). Nitrogen oxides are considered oxidants in the oxidation of BC by HNO or HNO combined with acids and NaNO18. The oxidation process changes the chemical structure of BC from -CHO functional groups to -COOH functional groups (as shown in Figure 5)17.

The changes in the morphology of the bacterial cellulose membranes after oxidation (Figure 1) and SEM images (Figure 2) revealed that 4 samples (OBC-6 h-25, OBC-6 h-40, OBC-12 h-25, and OBC-24 h-25) still retained their membrane shapes after oxidation, and the structures of the other membranes were damaged. In addition, the results also showed that cellulose hydrolysis occurred simultaneously during the oxidation process. When the temperature and reaction time are simultaneously increased, the membrane breaks into small pieces and dissolves in the reaction solution. Based on the appearance of the obtained membranes, the samples that could retain their morphology after the oxidation process, including OBC-6 h-25, OBC-6 h-40, OBC-12 h-25, and OBC-24 h-25, were further investigated.

The FT-IR spectra (Figure 3a) confirmed successful oxidation by the appearance of a new peak at approximately 1727 cm which was related to the stretching vibration of the -C=O bonds of carboxyl groups in the OBC membranes. In addition, the effects of temperature and reaction time on the chemical structure of OBC are shown by the amount of carboxyl groups (Figure 3b) formed in the BC membranes after oxidation. Overall, the carboxyl content of the OBC samples corresponds to the increase in temperature and oxidation time.

The results in Figure 4 compare the mechanical properties of BC and OBC oxidized with different parameters. The pristine BC sample had the highest mechanical strength. However, after the oxidation process, the mechanical properties of the OBC membranes decreased with increasing temperature and reaction time. The decrease in the mechanical properties could be attributed to the hydrolysis process that occurred at the same time as the oxidation. Hydrolysis leads to chain scission of the polymer chain of the OBC membrane, causing degradation of the membrane and reducing its physical and mechanical properties. Higher temperatures and longer oxidation times increase the hydrolysis rate, resulting in a significant reduction in the mechanical strength of the OCB samples 17. Combining the abovementioned titration results, it can be concluded that the OBC-6 h-40 membrane is the most ideal sample under the surveyed conditions. However, according to previous studies, gauze dressings used to cover wounds must have greater strength than human skin (1.8 MPa) so that the dressing cannot rupture easily when used19. As shown in Figure 4b, only three membranes (OBC-6 h-25, OBC-6 h-40, and OBC-12 h-25) met these conditions. Combined with the titration results (Figure 3b), it can be concluded that the OBC-6 h-40 membrane is the most ideal sample under the surveyed conditions.

The best sample (OBC-6 h-40) was used to measure the BCI to evaluate the hemostatic ability of the OBC membrane. The BCI value is determined based on the absorbance of hemoglobin at the appropriate wavelength. In other words, a sample that does not clot well and has a large amount of free red blood cells will result in a high BCI value. Conversely, samples with good coagulation and few free red blood cells will result in a low BCI 20. The lower BCI (Figure 4d) of the OBC membranes shows that oxidation helps improve the coagulation ability of BC membranes.

Comparison of the OBC products reported in previous studies and this work.

|

Sample |

Temperature (°C)/Time (h) |

Oxidized system |

Carboxyl content (%) |

Product form after oxidation process |

Strength (MPa) |

Elongation at maximum stress (%) |

Reference |

|

OBC-6 h-40 |

40 °C/6 h |

HNO3/H3PO4, NO2 |

16.18 ± 0.61 |

Membrane |

2.25 ± 0.19 |

87.6 ± 5.5 |

This work |

|

OC-24 hrs (A4) |

30 °C/24 h |

HNO3/H3PO4, NO2 |

20.93 |

Small pieces |

- |

- |

|

|

Nata-OC |

30 °C/24 h |

HNO3/H3PO4, NO2 |

28.6 |

Powder |

- |

- |

|

Conclusions

The results show that OBC membranes were successfully prepared by oxidizing BC membranes using a mixture of HNO/HPO-NaNO. Increasing the temperature and reaction time affected the chemical and mechanical properties of the OBC membranes. The appearance of the -COOH group in the FT-IR spectra confirmed the success of oxidation. When the temperature and reaction time increased, the mechanical characteristics of the OBC membrane decreased. This is due to hydrolysis, which occurred at the same time as oxidation. The simultaneous increase in temperature and reaction time causes intense hydrolysis. This caused the OBC to no longer retain its original membrane shape. In addition, under the examined parameters, OBC-6 h-40 was the best membrane.

LIST OF ABBREVIATIONS USED

BC: Bacterial cellulose.

OC: oxidized cellulose.

OBC: oxidized bacterial cellulose.

BCI: blood clotting index.

SEM: Scanning electron microscopy.

FT-IR: Fourier transform infrared.

COMPETING INTERESTS

The authors declare that they have no competing interests.

ACKNOWLEDGMENT

The authors gratefully acknowledge the financial support from the Department of Science & Technology and the People's Committee of Ben Tre Province, Vietnam, under contract 1845/H-SKHCN.

AUTHORS’ CONTRIBUTION

Kieu Thi-Thuy Nguyen: Investigation, Writing—original draft. Hoan Ngoc Doan: Writing—review & editing. Thao Thi-Phuong Nguyen, Huy Hoang Nguyen, Tin Dai Luong, Thai Anh Huynh, Khue Le-Minh Tran, Bao Gia Nguyen, Hai Huu Nguyen, Thu Ngoc-Minh La, Hai Do-Quoc Nguyen: Investigation, Thi-Hiep Nguyen: Conceptualization, Funding acquisition, Supervision, Writing—review & editing.