Synthesis of silica nanoparticles from rice husk ash

- Ho Chi Minh City of Natural Resources and Environment, 263B Le Van Sy Street, Ho Chi Minh City, Vietnam

- University of Science, Vietnam National University in Ho Chi Minh City, 227 Nguyen Van Cu Street, Ho Chi Minh City, Vietnam.

- Research and Development Center for Radiation Technology, Vietnam Atomic Energy Institute, 202A Street 11, Linh Xuan Ward, Thu Duc District, Ho Chi Minh City, Vietnam

Abstract

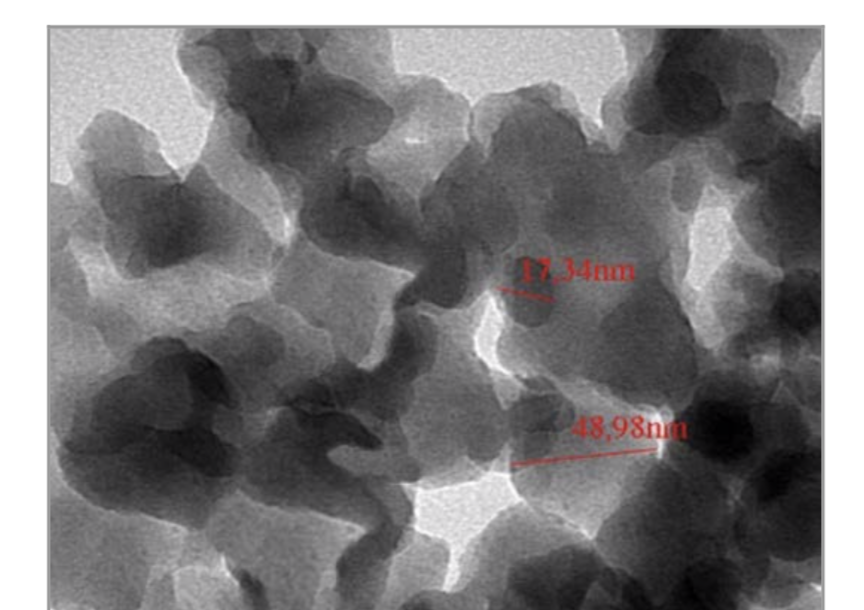

Silica nanoparticles (SiO2 NPs) were synthesized from rice husk ash (RHA) by chemical treatment and calcination. The size of SiO2 NPs evaluated by transmission electron microscope (TEM) was of 20 - 50 nm and the size distribution of SiO2 NPs measured by dynamic laser scattering (DLS) was of Gaussian mode. The X-ray diffraction (XRD) pattern with only one peak at 2θ ~ 220 confirmed the amorphous phase of SiO2 NPs. The Fourier transform infrared (FTIR) and energydispersive X-ray (EDX) spectra were also used to evaluate the functional groups and the purity of SiO2 NPs. The SiO2 NPs powder with high purity could be suitably produced by calcination of acid treated RHA at 7000C for 2h. The obtained SiO2 NPs product can be potentially used for numerous purposes of application, especially as filler in paints.