Study of the effects of process parameters on tool wear rate in powder mixed electrical discharge machining by Taguchi method

- Faculty of Mechanical Engineering, Hanoi University of Industry, Ha Noi, Vietnam

Abstract

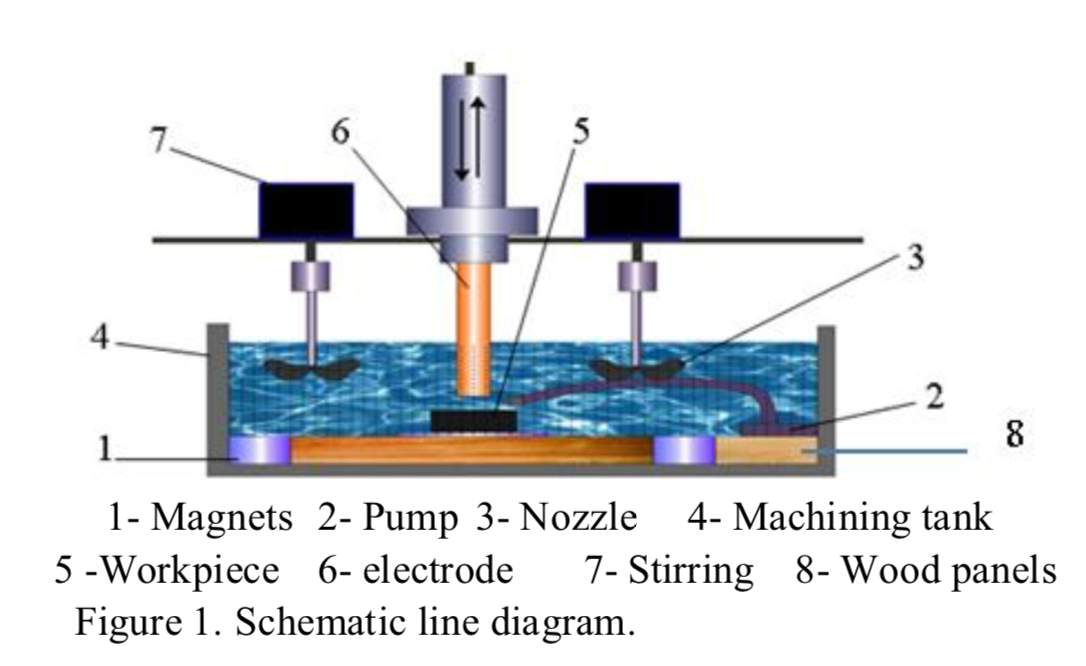

There have been various attempts to improve the surface finish after Electrical Discharge Machining (EDM) by polishing and other means. But if it is possible to improve the surface during machining it will shorten the machining time. From this viewpoint powder mixed EDM (PMEDM) is one of these processes. PMEDM not only imparts fine machined surface finish but also modifies the machined surface. However, it is necessary to understand the mechanism of PMEDM process. In this study, influence of process parameters to tool wear rate (TWR) of PMEDM using titanium (Ti) powder is presented. The objective of the study is to evaluate the main effects of workpiece material, tool material, polarity, pulse-on time, intensity of discharge, pulse-off time, and powder concentration on the TWR in PMEDM. They carried out the investigation based on the Taguchi method involving seven control factors with three levels for an orthogonal array L27 (1313).The results indicated that electrode material, electrode polarity, pulse on time, current and powder concentration were the most significant parameters that influenced the TWR. This result will be the basis for selecting the factors in further optimization studies.