The pyrolysis system for aluminum packaging with the highest aluminum recovery efficiency

- Department of Environmental Management, Faculty of Environment and Natural Resources, Ho Chi Minh City University of Technology (HCMUT), 268 Ly Thuong Kiet Street, District 10, Ho Chi Minh City, Viet Nam

- Viet Nam National University Ho Chi Minh City, Linh Trung Ward, Thu Duc District, Ho Chi Minh City, Viet Nam

Abstract

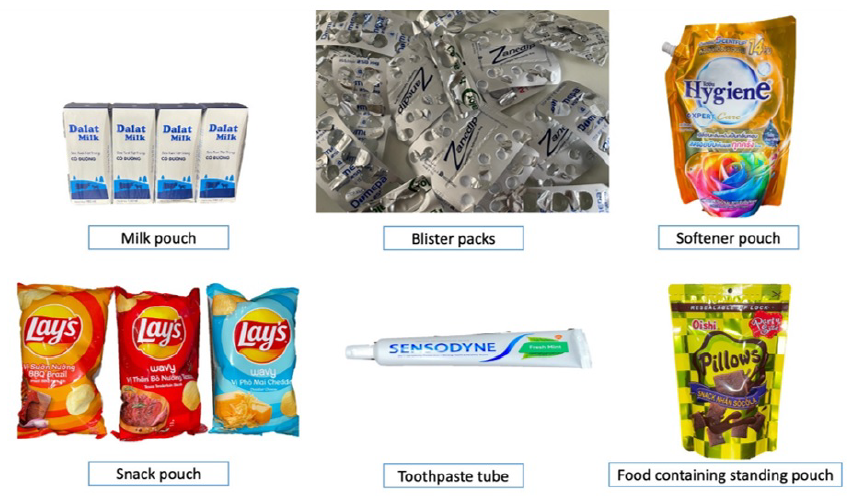

Recently, to save time, people have often preferred canned food because of its convenience, high nutritional value and safety compared with fast food. This has caused the amount of packaging waste in the world to increase rapidly, becoming one of the major dangers to the global environment. However, governments, environmentalists and scientists were soon aware of the dangers of this type of waste and soon developed improved methods to treat and minimize its impact on the environment. From the achievement of metal recovery in used products, this study also inherited the achievement of metal recovery in nonaluminum packaging products, namely, milk pouches, blisters, softener pouches, snack pounds, toothpaste tubes, and foods containing standing pouches, by pyrolysis. This study aimed to convert food packaging plastic wastes (MFPWs) into raw materials (aluminum and carbon particles) using three combined methods: pyrolysis and mechanical and chemical treatment. This experiment used a fixed-bed reactor in the laboratory to heat plastic packaging waste to obtain a solid fraction at a temperature of 800°C, and the retention time was 30 minutes. Food containing 98.64% of the samples yielded the most desirable results, while the second highest percentage of samples were produced from aluminum toothpaste tubes, for which the product contained 93.24%. Owing to the demand for metal recovery in all industries in general and in the food industry in particular, this research proposes identifying a packaging waste category from which pure aluminum can be recovered most efficiently by pyrolysis technology, and the feasibility of the results obtained will be tested shortly.

Introduction

The use of plastic garbage, electronic waste, building debris, and hazardous waste is also quickly growing. According to figures from the Vietnam Plastics Association (2019), the per capita plastic consumption in our nation in 2019 was 41 kg, which was ten times greater than the per capita plastic consumption in 1990 1. With 1.83 million tons of plastic garbage produced per year, Vietnam ranks fourth in the world, trailing only China, Indonesia, and the Philippines2. Aluminum-containing plastic packaging, including milk cartons, toothpaste tubes, and milk bags, is widely utilized in daily life. Aluminum-coated or aluminum foil packaging is efficient at preserving a product’s aroma and flavor. After aluminum and plastic bottles, metal bags are now favored. One of the laminar materials is nonrecyclable plastic packaging material or an equivalent substance. According to 2016 figures on the composition of household solid waste, approximately 15% of plastic is detected in MSW, with the majority being nonrecyclable plastic (10% of municipal solid waste). Multiple layers of metal and plastic make up the aluminum-coated plastic packaging material. This material is difficult to repurpose or transform into a secondary substance. However, the calorific value of aluminum-containing plastic packaging materials may exceed that of biomass since plastic packaging materials are predominantly made of carbon and hydrogen3. The benefits of packaging can be realized by transforming plastic packaging material into one that converts aluminum into energy and captures the metal. Thus, processing waste, energy application, bulk metal recovery, and reduction can be accomplished during final processing. Two interesting technologies that can be used for packaging materials are gasification and pyrolysis.

Aluminum-containing plastic packaging materials are the most common type of nonrecyclable plastic in municipal solid waste, excluding standard plastic bags. The aluminum-containing plastic packaging material is composed of many layers of plastic and metal. It is challenging to repurpose or reform this substance into secondary materials. However, the heating value of aluminum-containing plastic packaging material could be greater than that of biomass because most plastic packaging materials are composed of carbon and hydrogen4, 5. This packing material contains metals recoverable by thermal recovery processes. The use of aluminum-containing plastic packaging materials for accessing energy and collecting metals through residual material procedures is beneficial. As a result, waste treatment, energy application, metal recovery, and final disposal bulk reduction might be accomplished.

Due to the microstructure of MFPWs, this fraction of plastic waste was categorized as the most complex3, as this fraction of waste (MFPWs) consists of several layers of polymeric films laminated by a very thin aluminum layer with complex mechanical and chemical bonds that ensure food preservation for several days6, 7. In addition, the overall thickness of all these layers was calculated to be between 35 and 50 millimeters, which indicated low recyclability 8, 9. In addition, MFPWs account for approximately 20% of the total amount of plastic waste10; this value is a significant amount that should not be overlooked or minimized, especially given that the annual amount of plastic waste generated was estimated to be 350 million tons in 2018, which is equivalent to 70 million tons of MFPWs annually11, 12. Moreover, the enormous quantity of plastic trash, especially MFPWs, poses numerous environmental difficulties because it contains numerous contaminants and harmful substances13.

Thermal treatment via gasification and pyrolysis may convert plastic garbage into energy products at a 100% rate14. In recent years, waste-to-syngas gasification involving municipal solid waste, waste plastic and its generated fuel, synthetic polymers such as tires and PET, waste PVC cables, waste PCBs, automotive shredder residue, and electronic waste15 has been explored . Numerous research groups have declared accomplishments in solid waste treatment using novel methods that reduce environmental damage and restore resources. There have been numerous global investigations on the recovery of aluminum from various goods. The work of scientists from Lithuania and Russia might be mentioned as one of them. Scientists from Lithuania and Russia are evaluating the viability of aluminum recovery by pyrolysis, as well as the effect of process parameters on all aluminum components, as part of a joint study 15. In Asia, notably in Taiwan, scientists are also interested in metal recovery. Two Taiwanese researchers conducted the study, which demonstrated the successful recovery of metals (aluminum) and other types of products (syngas). As a consequence of these studies, the aluminum recovery rate is extraordinarily high, exceeding 85% for the majority of the reactions, and both the residue and purity are above 90% 14. In Vietnam, a country with a large volume of everyday garbage, sophisticated methods for garbage treatment and metal recovery have also been implemented. Researchers from the Institute of Science, Technology, and Environmental Management, Vietnam, experimented to determine the optimal settings for Cu recovery from electronic circuit industry trash. In addition, a study by Do Quang Khang et al. in 2009 investigated the pyrolysis of waste rubber to produce liquid fuel for industrial use, with research materials including waste bicycle tires and tubes acquired from Gold Star Rubber Company and waste motorcycles and automobile tires gathered at random from a collection site. The authors successfully determined the state of the input materials, the amount of oil separated at each temperature, and the chemical composition of the waste pyrolysis oil.

In this study, the highest aluminum recovery material concentration in a pyrolysis system was estimated by investigating different categories of plastic packaging waste containing aluminum. The first section provides an overview of the methods and several sample categories. The second part of the current work involved recovering aluminum from samples via various methods and then comparing the results to determine which material yielded the highest amount of aluminum recovery.

Materials and methods

Raw material selection

Aluminum-containing packaging waste is investigated and selected based on an estimate of aluminum recovery efficiency. In this test, no more than seven samples were evaluated to determine the sample with the best aluminum recovery efficiency (Figure 1). After collection, the raw materials were washed 5-7 times with clean water to eliminate dust, contaminants, and surplus milk products. The materials will then be exposed to the sun for 24 hours before being treated. At this stage, each sample was sliced into 5 mm × 10 mm pieces. The dried samples were then utilized for additional preliminary, final, and elemental analyses. The remaining sample was boiled and stored for further examination.

Six selected samples of aluminum-containing packaging waste.

Pyrolysis system

The weight of the sample obtained for each run ranged between 1 and 2 g. Before heating in the furnace, the raw material was measured and placed in each ceramic cup. The following experimental conditions were used: a temperature of 800°C and a retention duration of 30 minutes. This value is chosen to ensure that the sample burns out in the kiln and to ensure that there is sufficient sample output for the subsequent trials. Using such a high number of input samples also ensures device safety. The sample was placed in the furnace once the requisite temperature was reached and removed after a predetermined retention period. The sample will be cooled to room temperature before being sealed in Ziploc bags and stored for further experimentation. The timing of sample retention was determined from the international literature on the pyrolysis of aluminum-containing compounds (Figure 2).

Universal model of pyrolysis and gasification of fixed-layer waste packaging.

Extraction of Al and carbon particles

After pyrolysis, the residues were put into a 30 µm sieve to separate larger aluminum pieces from the micro carbon and aluminum particles. Large aluminum pieces were recovered and weighed. Microaluminum and carbon particles were put into a 98% HCl solution to dissolve aluminum in aluminum chloride (AlCl), after which the mixture was allowed to settle for 30 minutes. The remaining residue after settling was unreacted carbon, which was carefully separated from the solution of AlCl. After separation, the AlCl solution was dried at 105°C for 4 to 5 days. When the drying finishes, only solid AlClwill remain. The samples were subsequently weighed and converted into initial microaluminum weights through a conservative law. The weight of large pieces of aluminum and micro-aluminum combined is the total amount of aluminum recoverable from the initial sample. This weight will then be divided by the initial sample weight to obtain the aluminum recovery rate of that sample. This process was repeated 6 times for each sample to ensure unbiased results.

Results

Aluminum content

The aluminum content is defined by the addition of aluminum pieces and the resulting aluminum particles. After incineration, the aluminum content in each sample was determined according to the following equation:

Percentage of aluminum in each sample.

Blister packs are the samples that yield the most aluminum after incineration, with 0.8874 g of aluminum out of the initial 6.3803 g of sample (13.9077% of the sample weight). It is followed by a toothpaste tube and food-containing standing pouch, which yielded 0.6792 g aluminum out of 6.0622 g sample and 0.6131 g aluminum out of 6.1104, respectively. These three materials prove to be promising for recovering aluminum from plastic packaging waste. In contrast, when the softener pouch and snack pouch aluminum recovery rates are low (less than 1% for each). This result indicates that these patients were unsuitable for this study (Figure 3).

Product components

Product components are another factor to be considered when selecting the right material for this study. The products after incineration include aluminum pieces, aluminum particles, carbon particles, and other components. The results are depicted in the following chart (Figure 4).

The partitioning of Al into different types of output products.

Food contained yielded the most desirable results out of all the samples, with 0.6109 g out of 0.6193 g of products being aluminum pieces. The contents of the other products are also relatively low compared to those of the others. Blister packs and milk pouch products tend to decompose into aluminum particles more than the other products, with aluminum particle contents of 7.96% and 3.22%, respectively. Another great contender in this regard is the toothpaste tube, whose product contains 93.24% aluminum pieces, the second highest among the samples. However, because the carbon content yielded is higher than that of other promising materials, toothpaste can be drawn back.

Discussion

The complexity of the microstructure of plastic packages containing aluminum, as mentioned above, is the main reason for the inability to apply mechanical methods to recycle this kind of waste. The presence of many polymers (such as PE, PP, PVC, PS, and PET) also affects pellet behavior, and these materials are categorized as secondary raw materials for subpar applications since they lack uniformity and compatibility16, 17. Additionally, due to the toxicity of the solvents and gas emissions produced during the process, chemical techniques or separation methods involving solvents have not yet been used 18. Therefore, it is crucial to develop innovative technology and identify a practical solution to address waste issues as soon as feasible. Numerous cutting-edge recycling methods, including microbiological approaches, have been developed in this field. However, this method is currently being researched and has a variety of limitations related to its efficiency in degrading substances, the choice of microbes used, the pace at which the substance is recycled, the reaction time, .19. Since this type of waste is made of oil, re-extracting the oil and utilizing it as a renewable energy source to compensate for the gap in energy output would be a practical solution. Therefore, the most practical and efficient method is to thermally convert this waste to energy.

One of the primary choices for converting plastic waste to energy is thermal treatment via gasification and pyrolysis processes. In addition to the main objective of recovering aluminum, the main difference between gasification and pyrolysis is their different yielded energy products after the process. Overall, these 2 processes may turn up to 85% of the garbage into energy products20. Closed-loop technologies are used since they do not produce any waste that must be dumped in a landfill21. The products of thermal treatment include bio-oil, syngas, and char (solid residues).

Conclusion

By analyzing the yield of aluminum after incineration, the most suitable material for use in the study of utilizing gasification to recover aluminum is the food-containing standing pouch. While the amount of aluminum obtained from combusting this sample is not optimal, 98.64% of the products are aluminum cements, which is the best among the 6 chosen samples. Aluminum pieces are large and therefore easy to recover and process. In summary, the experiment was successful when the optimal conditions for the pyrolysis method for recovering aluminum from packaging waste were found, as was determining the aluminum recovery rate of this method. Changing this waste treatment method to replace traditional methods is common and can reduce side effects on the environment. In addition, the recovery of aluminum metal from this type of waste has also contributed to solving the very high demand for this metal in recent years.

Acknowledgments

This research is funded by Vietnam National University Ho Chi Minh City, VNU-HCM under grant number C2022-20-25. We acknowledge the support of time and facilities from HCMUT and VNU-HCM for this study.

Authors’ contributions

Sang Nguyen Huu and Dang Khoa Doan Nguyen: conceptualization; writing original draft; writing review and editing. Thi Ngoc Lan Thao Ngo: reviewing; revising; supervising. All authors are read and approved the final manuscript.

Abbreviations

MFPWs: metalized food packaging plastic wastes

Conflict of interest

There are no conflicts of interest to declare.