Spray-dried Encapsulation of Roselle (Hibiscus Sabdariffa) and Evaluation of Their Potential as Rich-antioxidant Compound

- Lab of Tissue Engineering and Regenerative Medicine, School of Biomedical Engineering, International University, Ho Chi Minh City, Vietnam

- Vietnam National University in Ho Chi Minh City, Ho Chi Minh City, Vietnam

- 1Lab of Tissue Engineering and Regenerative Medicine, School of Biomedical Engineering, International University, Ho Chi Minh City, Vietnam 2Vietnam National University in Ho Chi Minh City, Ho Chi Minh City, Vietnam

Abstract

There is a growing demand using rich-antioxidant compounds from plant extract to develop functional food products or biomedical products. In this work, we studied the impact of producing encapsulated roselle extracts with 1% w/v microencapsulated carrier as a powder rich in antioxidant properties. In particular, the roselle extract was subjected to spray drying using an acidified solution as a solvent. Combinations between maltodextrin and xanthan gum as wall materials were first tried for the roselle. Characterization of the spray-drying powder was confirmed by scanning electron microscopy (SEM), titratable acidity, anthocyanin content, and antibacterial and antioxidant activities. The results showed the addition of xanthan gum directly affects the morphology and antioxidant activities of the encapsulated materials. The particles presented a spherical shape with diameters ranging from 3 – 5 µm. The reduction of antioxidant activities and solubility were observed following the increasing concentration of xanthan gum. Thus, findings in this study have demonstrated that the obtained roselle spray drying powders can possibly be used as rich-antioxidant supplements for food, biomedical, and cosmetic industries.

Introduction

Naturally occurring compounds such as vitamins, polysaccharides, flavonoids, fatty acids, terpenes, and tannins serve as topical antioxidants by inhibiting oxidative stress 1. The use of natural herbs in food and health has a rich history, often with minimal adverse side effects. Recent research highlights their potential applications in the food and beverage industry and regenerative medicine, emphasizing their biocompatibility and safety. Notably, functional compounds from plants, particularly those rich in phytochemicals such as anthocyanins, are gaining attention for their antioxidant properties 2, 3.

Roselle (), an edible plant, has garnered significant interest for its potential applications across various industries4. This shrub, which belongs to the family, is renowned in many countries as a folk medicinal plant. Roselles contain numerous beneficial chemical components, including anthocyanins, flavonoids, and polyphenols, which support cardiovascular health, prevent hypertension, reduce fever, and protect liver function. Additionally, it is reported to possess antimicrobial, diuretic, digestive, and sedative properties. The anthocyanins in roselles, such as delphinidin 3-sambubioside, cyanidin 3-sambubioside, delphinidin 3-glucoside, and cyanidin 3-glucoside, are potent antioxidants, natural food colorants and antioxidant supplements for the cosmetic industry 4. However, these compounds are relatively unstable and can degrade due to environmental factors. Therefore, the application of technology to the processing of natural active ingredients in hibiscus flowers has become a research focus to increase the value of this product in various applications.

Spray drying and encapsulation represent advanced techniques for preserving the stability and functionality of biological compounds after processing. This method involves protecting the active substance—whether solid, liquid, or gas—by encasing it within a polymer matrix or high-molecular-weight substrate5, 6. This encapsulation process not only shields the active substance from environmental impacts but also maintains its properties and activity. Following encapsulation, the mixture undergoes spray drying to produce small particles of the active substances at the micro- or nanoscale. This process minimizes interactions with other environmental components, thereby preserving essential properties such as nutritional, color, antioxidant, and antibacterial characteristics. Despite the brief exposure to high temperatures during spray drying, this process can lead to the decomposition of compounds within the mixture5, 7. Therefore, it is crucial to optimize factors such as spray drying temperature, drying conditions, and the composition of encapsulating agents to develop an effective drying process.

In this study, we aimed to produce roselle-derived powder as a natural colorant and antioxidant supplement. The primary variable was the ratio of encapsulating agent used in the spray-dried roselle powder. Maltodextrin and xanthan gum were employed as encapsulating agents at a concentration of 1% w/v. Typically, the use of encapsulating agents in spray drying typically requires approximately 10–30% w/v to optimize the spray dryer8, 9, 10. However, some studies have reported the possibility of producing microencapsulated powders with less than 10% encapsulating agent, even at concentrations lower than 3% w/v11, 12. We hypothesize that reducing the amount of encapsulating agent may affect the efficacy of the spray dryer. However, reducing the concentration of encapsulating agent could result in a lower yield of solid powder but a higher proportion of extract content, benefiting the use and storage of the powder. Maltodextrin and xanthan gum are known to be compatible materials commonly applied in spray drying technology13. The presence of maltodextrin can improve drying and powder flowability, whereas the addition of xanthan gum, with its high colloidal ability, can enhance the encapsulated structure. As a thickening agent, xanthan gum is expected to support the encapsulation process of roselle extract via spray drying. After spray drying, the samples were dissolved, and their antioxidant capacity and anthocyanin content, which are key determinants of product applicability, were evaluated. Investigations were carried out on various characteristics, including the composition of the encapsulating carriers, the micromorphology of the roselle powder, and its physicochemical properties, to optimize the high antioxidant content of the spray-dried powder. Powder morphology was assessed by scanning electron microscopy. The anthocyanin content was measured on the basis of the cyanidin-3-O-sambubioside group, and the antioxidant activity was evaluated via the DPPH assay, which measures free radical scavenging ability. To our knowledge, this study is the first to introduce the use of maltodextrin and xanthan gum as encapsulating agents for roselle.

Materials and methods

Materials

Dry roselle (hibiscus) was purchased from Hichagol Co., Ltd., Hue, Vietnam. Acetic acid, citric acid, and sodium hydroxide were purchased from Xilong Chemical Co. Ltd. Potassium chloride and anhydrous sodium acetate were purchased from Guangdong Guanghua Sei-Tech Co. Ltd. Maltodextrin (DE: 10 - 12%) was received from Qinhuangdao Lihua Starch Co. Ltd. DPPH (2,2-diphenyl-1-picrylhydrazyl) and dimethyl sulfoxide (DMSO) were purchased from Sigma‒Aldrich.

Roselle extraction

The dry roselle flower was ground into a fine powder with a particle size of approximately 0.5 cm. An acetic acid 2% extraction solvent was prepared for the extraction process. Roselle powder was immersed in the solvent at a ratio of 4 g of roselle powder to 100 ml of extraction solvent. The mixture was incubated at 4 °C. After 24 h, the extraction mixture was collected. The solid residue after filtration was then subjected to another extraction process for 24 h. The final extracted material was stored at 4 °C for characterization.

Preparation of roselle

Four different formulas were spray-dried. Before microencapsulation, each encapsulating agent was dispersed in the roselle extracted solution and mixed until homogenization was reached. The encapsulation concentration was 1% w/v. The components of the wall materials and sample design are presented in

Preparation of spray-dried roselle powder

The SD-1000 Eyela (Eyela, Japan) was used to spray the encapsulating mixture. Once the mixtures were made, they were fed into the spray dryer. The inlet temperatures are set at 160 °C, and the outlet temperatures are set at 80 °C. A feed flow of the solution to be dried with a spray air flow of 0.7 m/min and a pressure drop of 180 kPa was used. To maintain the homogeneity of the solution, the encapsulated solution was gently mixed via a pump. After spray drying, the powders were weighed and stored in closed plastic bags, after which they were stored at -20 °C until evaluation.

Microencapsulation particle morphology

The powders were sputter-coated with gold at 10 kV, and their microstructural characteristics were analyzed via SEM (JSM-IT100, JEOL, Japan). Different magnifications of the sample were recorded. The size and morphological structure of the encapsulated roselle powder were measured via the ImageJ program, with 30 data points collected for each sample.

Solubility

The solubility of the powder was assessed via a method outlined in the literature 14. In a concise procedure, one gram of spray-dried powder was combined with 10 millilitres of distilled water, and the mixture was stirred via a magnetic stirrer for 5 minutes. The mixture was subsequently subjected to centrifugation at 4000 revolutions per minute (rpm) for 10 minutes. The resulting supernatant was carefully transferred to a Petri dish and subsequently dried at 105 °C for 2 hours. The solubility was determined by calculating the difference in solid weight between the reconstituted solution and the original solid sample.

pH and total acidity

The total titrated acidity expressed as % citric acid was determined through acid titration, utilizing 0.1 N NaOH and phenolphthalein as indicators. The initial pH value of each sample was determined via a pH meter. Following the pH measurement, 2–3 drops of phenolphthalein indicator solution were introduced. The titration then commenced with the addition of 0.1 N NaOH until the pH reached 7, signified by a color change in the solution. Throughout the titration process, the sample in the flask was swirled continuously. The volume of NaOH solution used in the titration was carefully noted. Finally, this recorded volume was used to calculate the total titrated acidity expressed as a percentage of citric acid. The equation for titratable acidity is as follows:

where:

: normality of titrant;

: volume of titrant;

: equivalent weight of predominant acid;

: mass of sample.

Total anthocyanin content

The total anthocyanin content (TAC) of the spray-dried powder was determined following a method outlined in the literature with slight modifications15. In a concise procedure, 50 mg of the sample was accurately weighed and mixed with 1 ml of distilled water, achieving a homogenous solution through vortex mixing. Two buffer solutions, namely, 0.2 M KCl buffer (pH 1.0) and 0.1 M acetate buffer (pH 4.5), were employed to dilute the sample mixture. To assess the absorbances of the diluted samples, measurements were taken at two distinct wavelengths, 520 nm and 700 nm, via a microplate reader. The content (mg/g of dry matter) was calculated via the following equation:

= ( - ) pH 1 - ( - ) pH 4.5

: volume of diluted samples;

: 96-well plate length (0.286 cm);

: molecular weight cyanidin-3-glucoside, 449.2 g/mol; ɛ = 26,900 L/mol.

DPPH free radical scavenging activity

DPPH, which stands for 2,2-diphenyl-1-picrylhydrazyl, serves as a reagent used to measure the antioxidant activity of substances. In brief, the procedure involves the preparation of spray-dried powders mixed with DI at different concentrations (5, 10, 15, 30, and 45 mg/ml). DPPH was simultaneously dissolved in DMSO (0.1 mM). Subsequently, 20 microliters of the sample at various concentrations were added to wells in a 96-well plate, along with 180 microliters of the DPPH reagent. The reaction mixture was then incubated for 30 minutes in the dark, and the absorbance was measured at 517 nm. The percentage of DPPH-scavenging activity was calculated via the following equation:

where:

: the optical density value of the blank;

: optical density value of the test sample.

Evaluation of the antibacterial activity of the roselle powder

The antibacterial activity of the roselle powder was evaluated via the use of two representative microorganisms: () (ATCC 25922), a gram-negative bacterium, and () (ATCC 25913), a gram-positive bacterium. The minimum inhibitory concentration (MIC) was determined via a classical dilution method adapted to 96-well microtiter plates. Each assay was performed in triplicate. Serial dilutions of roselle powder were prepared in the wells, and each well was inoculated with a standardized bacterial suspension. The plates were then incubated under appropriate conditions for bacterial growth. The MIC value was defined as the lowest concentration of roselle powder that inhibited visible bacterial growth after the incubation period.

Statistical analysis

All the experiments were performed in triplicate, and the results are presented as the means ± standard deviations. Statistical analysis was conducted via one-way ANOVA for all tests, followed by Tukey’s post hoc analysis to determine significant differences between groups. A p value of less than 0.05 was considered statistically significant.

Results

Physio-chemical profile of roselle extract

The extraction step for the dried roselle powder product was meticulously performed to isolate valuable compounds such as anthocyanins, vitamins, flavonoids, and phenols from the roselle flower. In this study, cold brew extraction was performed with 2% acetic acid utilized as the solvent, ensuring efficient extraction of these bioactive components. Initially, the properties of the extract solution were evaluated, with a focus on parameters such as pH, acid content, anthocyanins, and antioxidant capacity, before proceeding to the spray drying stage.

During the initial evaluation, the solid content in the extracted sample was determined to be 10 mg/ml. The pH and acid content of the extract were measured via titration methods, revealing an acid content value of 2.8%. The anthocyanin content in the roselle extract was 50.06 ± 2.19 mg/L, indicating the significant presence of these potent antioxidants. Additionally, the antioxidant capacity, as assessed through DPPH scavenging activity, had an IC50 value of 2.83 ± 0.03 mg/ml. The extraction process effectively evaluated the anthocyanin, antioxidant, and total titratable acidity (TTA) contents of the initial roselle extract. As anticipated, the roselle flowers presented high antioxidant capacity and high anthocyanin content. Identifying these components at the extraction stage represents a crucial initial success in the overarching goal of developing a roselle powder product with increased antioxidant and anthocyanin contents. The parameters of the extraction solution are summarized in Figure 1.

Physio-chemical profile of roselle extract extracted with acetic acid.

Microencapsulated-roselle powder by spray drying

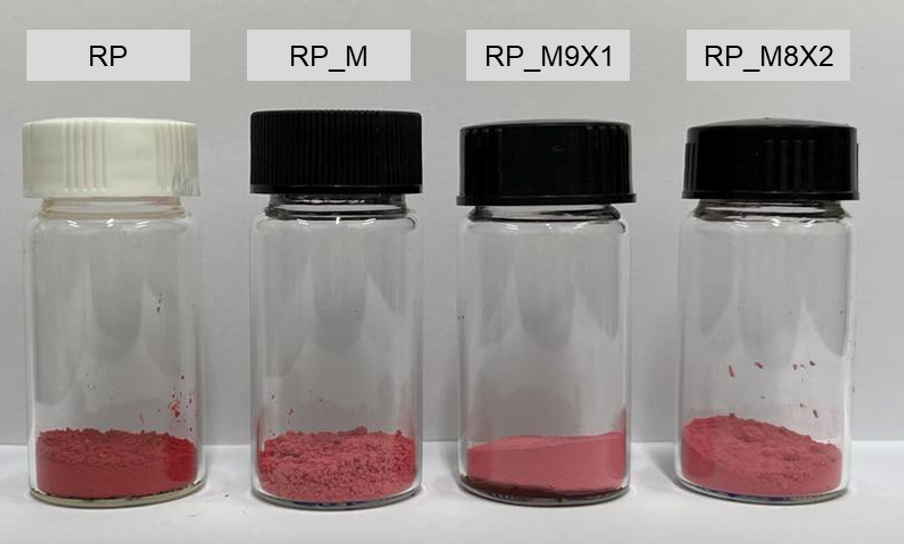

After the spray drying process, the morphology of the roselle powder was evaluated. In general, microencapsulated roselle powder consists of fine particles in its dry form, despite some changes being observed among the coating and uncoating treatments. Figure 2 shows images of the spray-dried roselle powder under different blending treatments. In its uncoated form, the pure roselle powder exhibited a deep red color. Owing to the lack of coating, the use of pure extract in spray drying systems is challenging. The high-temperature drying treatment caused the sugar components in the crude roselle extract to reach the glass transition state and adhere to the drying system, resulting in only a minimal amount of pure powder remaining after the spray treatment. For particles coated with maltodextrin (MD) or xanthan gum (XG), at a 1% coating agent concentration, the roselle powder tends to be pinkish-red. The red shade is slightly lower than that of the uncoated powder because of the presence of the coating agents.

Spray-dried roselle powders subjected to various encapsulation treatments.

The morphology and microscopic size of the roselle powder were also evaluated via SEM. Figure 3 shows microscopy images of the different blending formulas of the roselle powder. SEM analysis of the uncoated roselle powder revealed smooth surfaces with visible bridges between the particles, indicating agglomeration (Figure 3A). In contrast, powder formulations mixed with a coating agent have uniform round particles of varying sizes depending on the content of the coating agent and the xanthan gum component. At a 1% coating agent concentration, the particle size was approximately 3–4 µm. Figure 3B shows that particles coated with maltodextrin alone have smooth surfaces with a 3.4 µm diameter (

Micromorphology of roselle powder. (A) RP (roselle extract without encapsulation); (B) RP_M; (C) RP_M9X1; (D) RP_M8X2. Scale bar: 5 µm.

Sample designed for microencapsulation of roselle extract.

|

Sample |

Encapsulating material | |

|

|

MD (% w/v) |

XG (% w/v) |

|

RP |

- |

- |

|

RP_M |

1 | |

|

RP_M9X1 |

0.9 |

0.1 |

|

RP_M8X2 |

0.8 |

0.2 |

Solubility and particle size of roselle spray-dried powders.

|

Sample |

Solubility (%) |

Particle size (µm) |

|

RP_M |

94.27 ± 0.28 |

2.6 ± 1.5 |

|

RP_M9X1 |

41.18 ± 1.38 |

2.7 ± 2.1 |

|

RP_M8X2 |

32.52 ± 1.54 |

2.8 ± 1.4 |

Physio-chemical profile of the microencapsulated roselle powders.

|

Sample |

pH (2 mg/ml) |

TTA (100 mg) |

Anthocyanin content (mg/g) |

DPPH IC50 (mg/ml) |

MIC (mg/ml) | |

|

|

| |||||

|

RP |

2.8 ± 0.1 |

32.9 ± 0.4a |

50.1 ± 2.2a |

2.8 ± 0.3a |

24.7 ± 0.9a |

31.8 ± 1.8a |

|

RP_M |

2.4 ± 0.1 |

16.6 ± 1,3b |

41.3 ± 1.5b |

3.3 ± 0.1a |

17.5 ± 4.3a |

37.8 ± 1.5a |

|

RP_M9X1 |

2.9 ± 0.4 |

14.9 ± 0.7b |

38.4 ± 0.9c |

4.0 ± 0.5a |

41.3 ± 2.9b |

32.9 ± 0.4a |

|

RP_M8X2 |

2.4 ± 1.0 |

13.7 ± 2.0b |

38.0 ± 0.9c |

4.6 ± 1.1a |

35.1 ± 1.9b |

25.7 ± 3.1a |

|

Difference letters represent for significant different data at the level 0.05 | ||||||

This increase in particle size is necessary to reduce the surface area ratio of the sample, thereby limiting the influence of temperature and environmental humidity on the extract molecules encapsulated in the carrier layer. This hypothesis can be confirmed by the significant changes in the solubility of the microencapsulated material. As the content of XG in the microencapsulated carrier increases, the solubility of the powder decreases. At the highest content of XG (RP_M8X2), the solubility of the roselle powder was only 32%, three times lower than that of the treatment with only maltodextrin. This reduction shows that by adding XG into the encapsulated component, the particles tend to be more hydrophobic, in which XG reinforces the microencapsulated wall, increasing the difficulty of penetration of water molecules into the particle.

Physio-chemical profile of the microencapsulated roselle powder

Discussion

To investigate the production of hibiscus powder with high antioxidant capacity, a spray drying method using maltodextrin and xanthan gum was employed in this study. To perform the spray drying method effectively, this study involved combining an effective extraction process with potential encapsulation treatments at 1% w/v to create roselle spray-dried powder. Our results confirmed the successful creation of hibiscus powder from the extract. Spray drying experiments using maltodextrin and maltodextrin mixed with xanthan gum produced hibiscus powder at various concentrations and encapsulation ratios. On the basis of the results presented in

Conclusions

In this study, spray drying experiments using maltodextrin and maltodextrin mixed with xanthan gum successfully produced hibiscus powder at various concentrations and encapsulation ratios. A 1% w/v encapsulation mixture effectively formed small spray-dried granules (1–5 µm). Hibiscus powder without encapsulation was unsuitable for spray drying because of the difficulty in obtaining powder samples. Treatment with only maltodextrin resulted in stable values with relatively high anthocyanin contents, and antioxidant properties were observed. With a 1% w/v coating agent, an increased xanthan gum content decreased the stability of the roselle powder, with the lowest anthocyanin and DPPH values in the RP_M8X2 sample. SEM images revealed more wrinkled and distorted particles with xanthan gum. The presence of XG reduces the surface area and may reinforce the coating agent composition, which can enhance protection from environmental influences. Despite these findings, all the experiments revealed that spray-dried roselle seeds retained their antioxidant capacity and color, as indicated by the anthocyanin and IC50 results from the DPPH experiments. These findings confirm the successful production of roselle powder with high antioxidant capacity, suggesting significant potential applications in food, cosmetics, and pharmaceuticals for regenerative medicine.

LIST OF ABBREVIATIONS USED

DPPH: 2,2-diphenyl-1-picrylhydrazyl

DMSO: Dimethyl sulfoxide

SEM: scanning electron microscopy

TAC: total anthocyanin content

MIC: minimum inhibitory concentration

TTA: total titratable acidity

MD: maltodextrin

XG: xanthan gum

COMPETING INTERESTS

The authors declare that they have no competing interests.

ACKNOWLEDGMENT

The authors gratefully acknowledge the financial support from the Department of Science & Technology and the People's Committee of Ben Tre Province, Vietnam, under contract 271/HĐ-SKHCN. We also thank all the members of the TERM laboratory for useful discussions and support.

AUTHORS’ CONTRIBUTION

Vo Minh Quan: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Visualization, Writing – original draft, Writing – review & editing, Project administration

All authors reviewed and accepted the manuscript.